In terms of conferences and meetings, concepts, which could once only be discussed or drawn can now be printed into tangible objects. Team building exercises, or brainstorming could involve the design and production of prototypes almost ready for market. Gift bags once filled with vouchers and brochures, could now be filled with actual products.

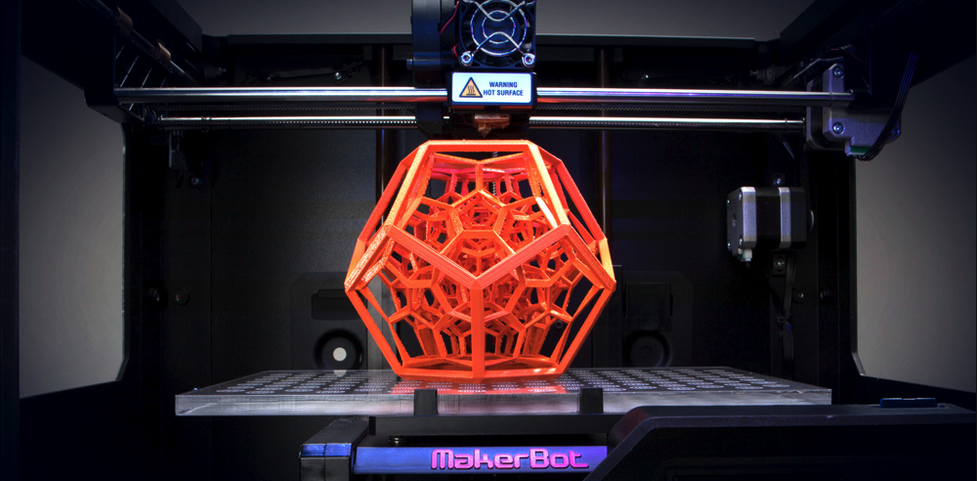

In a world where the technology for 3D printing has become available, the process now involves designing a series of instructions to be fed to the 3D printer. At the press of a button the prototype can be produced and presented. Any changes can be worked into the instructions so that the final prototype stage is reached fairly quickly. Design of a new product was often restricted by the limitations of the available manufacturing infrastructure and labour. 3D printing encourages innovation as it allows a freedom in designing, which is no longer bound by such limitations. As the technology advances and 3D printers become smarter, cheaper and more accessible the boundaries of 3D printing appear to be limitless. Production of items could take place in offices, or even the home. The future may see us re-producing famous artwork for our scrutiny, or to produce food for consumption or even human organs for transplants. Children could ‘print’ their own toys, adults their own jewellery, the list goes on. The possibilities are endless. This technology is fast becoming an accessible and innovative tool that could revolutionise the manufacturing world as we know it. Comments are closed.

|

Categories

All

Archives

April 2020

|